How the engine runs safely

01 December 2020 – The production of new climate-friendly fuels is technically possible, as a previous contribution to the example of the platform chemical methanol explained. In order to bring future low-CO2 fuels to technical maturity, it is important on the one hand to further optimize the production processes and on the other hand to ensure the compatibility of the new fuels with existing technical systems. Although regenerative fuels are new, the application technology issues remain the same:

- Ageing/oxidation stability

How do fuel properties change over certain periods of time under defined external influences, such as temperature? - Miscibility

Can new renewable fuels be mixed well with other alternative and conventional fuels? How do the fuel properties change when fresh and old goods are mixed together? - Interactions

Do interactions between fuels occur caused by blending? - Material compatibility

Do interactions occur between fuels and the materials of fuel-carrying components, such as corrosion, increased wear or swelling seals? - Overall system compatibility

What about the overall system compatibility of a fuel?

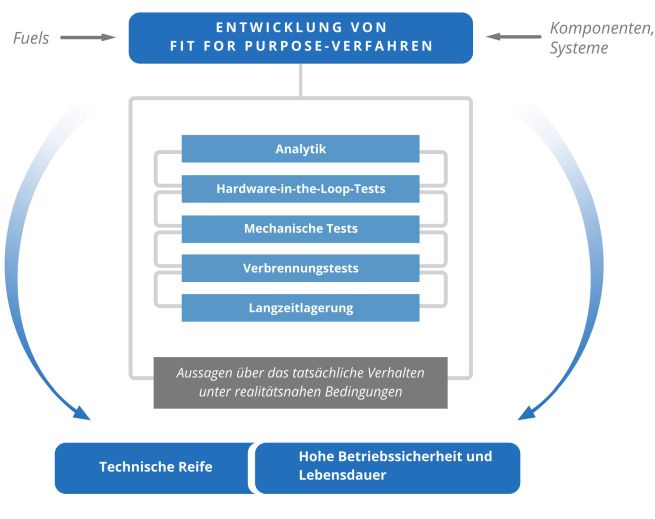

Classic testing looks at the fuels on the one hand and the components on the other, but often the complex interplay of fuels and technologies/systems is not the focus of the investigations. Sometimes there is also a lack of fast and cost-effective test procedures. OWI Science for Fuels and TEC4FUELS, on the other hand, have adopted a holistic view of the interactions. OWI develops application-oriented “Fit for Purpose” test procedures that simulate real operating conditions in the laboratory and supplement classic test methods. „TEC4FUELS further develops these test methods from technical maturity to market readiness and thus carries out fuel and component tests for the automotive industry, shipping, component manufacturers and the petroleum industry as a service“ explains TEC4FUEL´s managing director Klaus Lucka.

Central criterion: operational safety

On the basis of the results of the test procedures, valid statements about the behavior of fuels, additives, components and entire systems under application-related conditions are possible, revealing, for example, fuel- and material-related risks. In addition, valuable material data on the changing chemical-physical properties of fuels in the course of aging processes are obtained, which can be used for fuel condition monitoring. On the basis of the constantly growing collection of know-how and data, OWI and TEC4FUELS can also act as consultants, pointing out technical paths and evaluating manufacturing processes and the potential of new fuels and market opportunities.

Test procedures developed at OWI and carried out by TEC4FUELS on behalf of customers include the rapid test for diesel injectors (ENIAK) and the ATESFUELS test, which can be used to investigate the compatibility of middle distillates with engine and heating components. These tests ensure that the industry does not experience any surprises during market launches. Companies that enter a field or fleet test or even a market launch with a new fuel, component or system need maximum operational reliability to protect themselves against recourse claims and damage to their image. „The knowledge gained from the application of the test methods not only provides an important basis for decision-making in product development, but also for the quality assurance of existing products“ says Mr. Lucka. „Ultimately, they lead to a high level of operational safety and service life of technical components.“

Which test methods are suitable for fuel and component tests, and what strengths they have, can be read in the third part of our series of articles.