Test of biogenic marine fuels

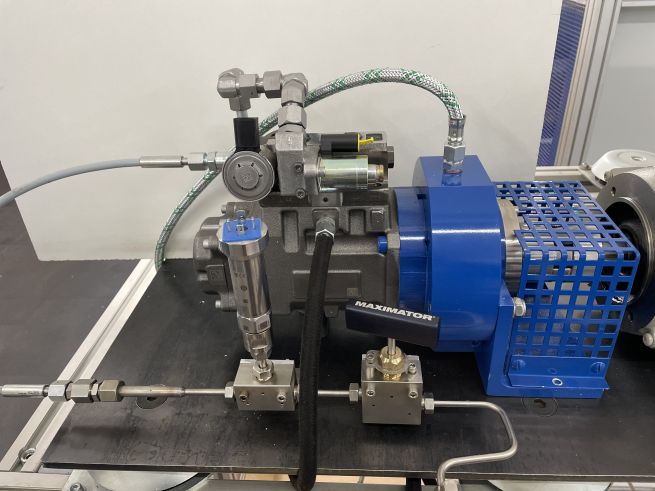

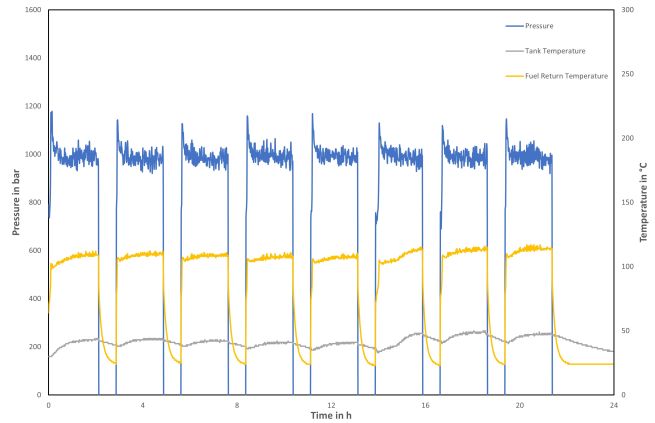

23 September 2021 – Tec4Fuels GmbH has set up a non-motor hardware-in-the-loop test rig for marine fuels in the EU research project “IDEALFUEL” and successfully performed a first test run with marine gas oil as reference fuel. Over a test run time of 100 hours at a pressure of 1,000 bar, no incompatibilities arose with the materials of the fuel-carrying components.

In the IDEALFUEL project, an international consortium is developing new, efficient and cost-effective methods for producing low-sulfur heavy fuel oils for marine use from wood-based non-food biomass. Tec4Fuels will perform hardware-in-the-loop testing of the IDEALFUEL bio-heavy fuel oil in the project to assess its drop-in capability and material compatibility. For this purpose, the IDEALFUEL will be mixed in different proportions with the baseline fuel in accordance with the ISO 8217 standard and fed in a circuit through the high-pressure pump of a 4-stroke engine under forced conditions (increased pressure and temperature) in the test rig. This circuit contains around 30 liters of fuel.

This stress test for fuels and components enables valid statements to be made about the behavior of the fuel in interaction with the materials using a comparatively simple test setup and in a relatively short time. The investigation serves both the quality assurance of the IDEALFUEL and the operational safety of the fuel-bearing components of engines.

The goal of the IDEALFUEL project is to develop the new technologies and processes from the current laboratory scale to pilot scale to demonstrate the performance and compatibility of bio-heavy fuel oil across the blending range in marine fuel systems and marine engines. In addition, IDEALFUEL will conduct an environmental impact assessment and life cycle analysis (LCA) to verify and demonstrate the soundness of the environmental, social and sustainability aspects of the developed technologies, processes, products, solutions and logistics.

Visit the website of the EU research project IDEALFUEL

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 883753.